In Focus

- Leveraging NMAC Information Using Game-Changing Technology

- Going Back to the Basics to Improve Air-Operated Valve Performance

- One-Stop-Shopping for All Your Lubrication Needs

- LEMUG Meeting addresses Component Engineer and Vendor Interaction

- Large Electric Motor Users Group Reviews Environmental Qualifications for Electric Motors

- Comprehensive Motor Resource

- KKL, EPRI Co-Sponsor First European Foreign Material Exclusion Workshop

- Work Planning Managers/Supervisors Identify Key Issues and Prioritize Activities

- Circuit Breaker Users Group Update

- Improving Emergency Diesel Generator Performance

- Japanese Reliability-Centered Maintenance–Condition-Based Maintenance Users Group Update

NMAC Meetings and Workshops

- 2012 Joint EDG Owners Group Conference

- NMAC Holds Workshop for Vodo-Vodyanoi Energetichesky Reactor-Style Pressurized Water Reactors Members

- Pump Users Group Meeting

- Terry Turbine Users Group Meeting

- 2011 Transformer and Switchyard Users Group Meeting

- Transformer and Switchyard Users Group Circuit Breaker Workshop

- Pressure Relief Device Interest Group—Update and Status

- 2012 NMAC Meetings

NMAC Members and Personnel

In Focus

Leveraging NMAC Information Using Game-Changing Technology

As covered in the previous NMAC Memo, NMAC has been exploring new ways to deliver NMAC information using enhanced digital technology. The main objective is to place the maintenance best practices captured by NMAC and the industry back into the hands of the maintenance worker in a useful and portable format. The old portable document format and hard-copy reports are seldom seen by the maintenance mechanic. The only information that would trickle down to the worker is the information found within the work procedures.

The answer to the issue is believed to be found in the new NMAC Air-Operated Valve (AOV) app. Using the latest technologies, NMAC has developed a computer application that pulls together maintenance instruction, best practices, computer-aided design animation, visualization, and user interaction to promote the ultimate maintenance experience. The app will also have the ability to store plant procedures and other information needed in the field and will allow a worker to reference this as a quick refresher for a maintenance task. A modern maintenance mechanic can have all that is needed with the push of a button rather than having to carry around a large volume of paper. The figure below demonstrates the use of the mobile app in the field.

Evolution of NMAC maintenance guides from hard copy to mobile apps brings NMAC information into the hands of the worker with a touch of a button

What makes the app unique is that there are two versions: a tablet version and a PC version. The PC version of the app combines all the features of the tablet version but adds an interactive element through the Learn mode. The interaction allows maintenance personnel, engineers, and even work planners to sit at a computer station and learn/refresh about the operation and critical maintenance activities of an AOV. The Learn mode consists of step-by-step instruction and interaction through a tool bin where the user has to select the correct tool to complete the task. Additionally, the PC version incorporates a test module. The test module allows for quick testing of supplemental workers or just-in-time training for return workers.

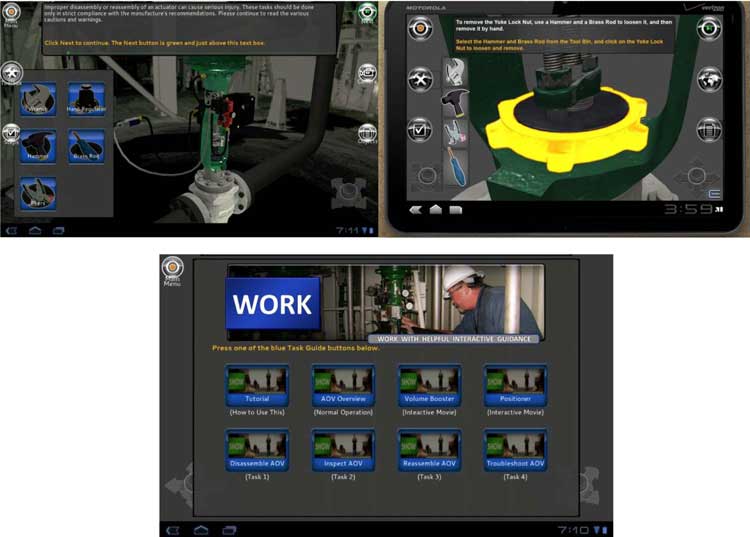

The tablet version (see the figure below) is aimed at field activities for the maintenance mechanic. The tablet version will have the ability to provide maintenance instruction including reassembly and disassembly along with troubleshooting and inspection. In conjunction with plant procedures, this will allow the worker to have visualization that can be combined with plant procedures to help lessen the human factor that seems to plague the industry.

Screen shots of the tablet app identifying work tasks, user-friendly interface, and easy maintenance instructions

Look for this AOV app to be available in the second quarter of 2012.

For more information, contact Mike Pugh, 919.812.5162, mpugh@epri.com or Nick Camilli, 704.595.2594, ncamilli@epri.com.

Going Back to the Basics to Improve Air-Operated Valve Performance

During the last few years, the industry has focused on improving the performance of air-operated valves (AOVs). When the Institute of Nuclear Power Operations placed balance-of-plant (BOP) AOVs on the key issue list, the stakes were raised. Although the overall performance of BOP AOVs was not terrible, there were enough industry events to force down power or generation loss, therefore, challenging the industry’s forced loss rate goal and resulting in increased awareness of AOV.

When times get tough, sometimes one has to step back to the basics and reexamine the program as a whole and the elements that make up the program. It only takes one weak link to challenge the overall performance of the program. Elements of a successful AOV program are outlined in NX-1018, which was originally issued in March 1999 by the Joint Owners Group (JOG). The objectives of the JOG program document were to do the following:

- Provide assurance that critical AOVs are capable of performing their risk-significant functions under design-basis conditions

- Provide a means to prioritize resources so that the most risk-significant AOVs receive proper testing and preventive maintenance

- Optimize AOV maintenance and performance to achieve significant economic savings

The nine elements outlined under the JOG program are scoping and categorization, set-point control, design basis reviews, testing, preventive maintenance, training, feedback, documentation and data management, and tracking and trending. There are supporting NMAC reports to assist with these elements, and the table below outlines this relationship.

Relationship Between NMAC Reports and AOV Program Elements

AOV Program Elements as Identified Through the JOG |

Supporting NMAC Reports |

|

Scoping and Categorization |

N/A |

|

Set-Point Control |

Air-Operated Valve Evaluation Guide—Revision 1 (1022646) Guide for Evaluating Air-Operated Valve Uncertainties and Actuator Setup Parameters (1006555) |

|

Design Basis Reviews |

Air-Operated Valve Evaluation Guide—Revision 1 (1022646) |

|

Testing |

Air-Operated Valve Diagnostic Testing Guide (1022954) |

|

Preventive Maintenance |

Air-Operated Valve Maintenance Guide: Revision 2 (1016682) Valve Positioner Principles and Maintenance Guide (Updated to Include Digital Valve Positioners) (1022989) PMBD v2.1 (Preventative Maintenance Basis Database) (1018758) Valve Packing Performance Improvement: Sealing Technology and Plant Leakage Reduction Series (1000923) Compression Fitting Application Manual (1016994) |

|

Training |

Air-Operated Valve Actuator Maintenance Application |

|

Feedback |

N/A |

|

Documentation and Data Management |

N/A |

|

Tracking and Trending |

Air-Operated Valve Diagnostic Testing Guide (1022954) |

NMAC is a resource, and a great deal of good information has been collected over the years and published. There is guidance from calculating margins to preventive maintenance tasks to diagnostic testing and uncertainties.

For more about the AOV work performed by EPRI, contact Nick Camilli, 704.595.2594, ncamilli@epri.com.

One-Stop Shopping for All Your Lubrication Needs

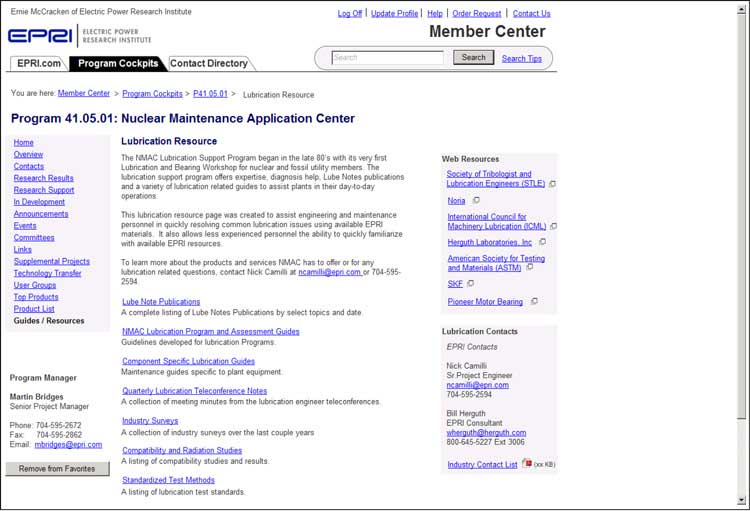

In today’s technology-driven world, everything is nearly a click away. NMAC has locked in on this concept with the previously developed Pump and Motor Resource webpages. A new addition to the NMAC program cockpit is the Lubrication Resource page, which will be available by the end of 2011 and is shown in the figure below.

A screen shot of the new Lubrication Resource webpage

The Lubrication Resource page was created to assist engineering and maintenance personnel in quickly resolving common lubrication issues using available EPRI materials. It also provides less experienced personnel with the ability to quickly familiarize themselves with available EPRI resources. All of the Lube Note publications, lubrication guides, quarterly lubrication teleconference notes, industry surveys, and radiation studies are included on the webpage. Additionally, references to ASTM International publications and other web resources are included.

To access the Lubrication Resource webpage, go to www.EPRI.com and then the NMAC program cockpit. On the left side, there will be a tab for Resources. The Lubrication Resource page is located there.

For more about the NMAC lubrication support program and elements, such as this new webpage, contact Nick Camilli, 704.595.2594, ncamilli@epri.com.

LEMUG Meeting addresses Component Engineer and Vendor Interaction

The August 2011 meeting was held in Portsmouth, Virginia, August 15–18, 2011. An environmental qualification (EQ) workshop was held before the meeting.

Because EPRI has developed a qualified system for rewinding electric motor stators and, as a follow-up to the EQ workshop, the first presentation provided an update to the work being done to establish activation energies for the materials used in the EPRI rewind system.

The importance of providing oversight to work being done by vendors still remains an important task for users such as witnessing a stator vacuum pressure impregnation (VPI) process, as shown in the figure on the next page. Two presentations during this meeting addressed vendor oversight—one from a utility user perspective and one from a vendor or service provider perspective. The importance of conveying the desired work and providing clarity was emphasized during the utility presentation, and ensuring that the right work is done and confirmed by the user was the focus of the vendor presentation. The importance of witness and hold points during the refurbishment and/or rewind process was conveyed during the vendor presentation.

Preparing a stator for VPI treatment

Used with permission from Public Service Electric & Gas

Certain in-process tests and confirmatory testing should be done to confirm stator condition. There was a presentation on reviewing stator surge test waveforms. These waveforms are reviewed and compared to determine whether the stator has good turn-to-turn insulation integrity. Another test that can be done is the immersion test to prove that the stator has a thoroughly sealed insulation system. This type of testing was described, and its application was discussed.

One concern that vendors and motor owners face is whether to add leads to the motor before or after the VPI cycle. The pros and cons to each approach were presented during a presentation. Personnel having motors rewound would benefit from reviewing this presentation.

The January 2012 workshop and meeting have been planned, and the agenda is under development. The workshop will be a followup to the EQ workshop conducted at the August meeting.

Plan to attend the meeting, which will be January 30 through February 2, 2012, in New Orleans, Louisiana.

For more information, contact Wayne Johnson, 704.595.2551, wejohnson@epri.com.

Large Electric Motor Users Group Reviews Environmental Qualifications for Electric Motors

A workshop was held at the August 2011 Large Electric Motor Users Group (LEMUG) meeting to review the environmental qualification (EQ) requirements that affect the consideration for electric motors.

A horizontal motor on a shake table

Used with permission from Tom Brewington of Wyle Labs

Because of the aging workforce and the lack of new plant designs and construction, the nuclear industry has been losing its expertise in EQ, and the EQ skills are less common among plant personnel than they have been in the past. Many companies made the assumption that EQ work was over, and all the industry had to do was maintain equipment. However, this assumption has not held fast. The extension of plant operating licenses and the increase in plant output has caused plants to revisit EQ requirements.

As EQ motors age, they require maintenance. Rewinds are becoming more frequent, and critical EQ spares are being planned for purchase. Several plants have expressed an interest in becoming more knowledgeable about the history of EQ, options for repair and rewind of EQ motors, available EQ insulation systems, and procurement requirements for new EQ motors.

The LEMUG EQ workshop addressed the history of EQ. It also addressed the industry guidance for the implementation of environmental requirements in the nuclear industry.

Because many of the attendees were mostly motor component persons, much of the background information for EQ was presented to bring attendees up to date.

The workshop presented the information by covering EQ requirements from an equipment type perspective—electrical and mechanical. This equipment can be found inside and outside containment areas. The EQ requirements relate to seismic, temperature, humidity, pressure, chemical, and radiation.

The workshop covered the traditional categories of plant equipment. They are as follows:

- Commercial

- Safety-related

- Class 1E—non-EQ

- Class 1E—EQ

The workshop held at the August 2011 LEMUG meeting provided background information on EQ and affected equipment. During the January 2012 LEMUG meeting, a follow on workshop will focus on the applicability of EQ requirements for electric motors. There are certain materials and activities that can affect EQ requirements and must be addressed to maintain EQ requirements.

EQ requirements affect primarily organic materials. The primary organic component of an electric motor that EQ testing has focused on is the insulation system that makes up the stator windings. However, there are other components that are made of organic compounds, and these are as follows:

- O-rings

- Gaskets

- Motor leads

- Sealants

- Coatings

- Lubrication

The goal of the August 2012 workshop is to bring the attendees up to date on electric motor EQ requirements and review methods for extending the qualified life of some electric motors.

There was a tour at the Electric Motor and Contracting (EMC) Company in Chesapeake, Virginia, that was provided in association with this workshop. EMC recently added a facility to handle contaminated electric motors and installed a new test board. The tour provided attendees an opportunity to witness motors in various stages of repair and testing.

If you have suggestions for training topics or other LEMUG activities, contact Wayne Johnson, 704.595.2551, wejohnson@epri.com.

Comprehensive Motor Resource

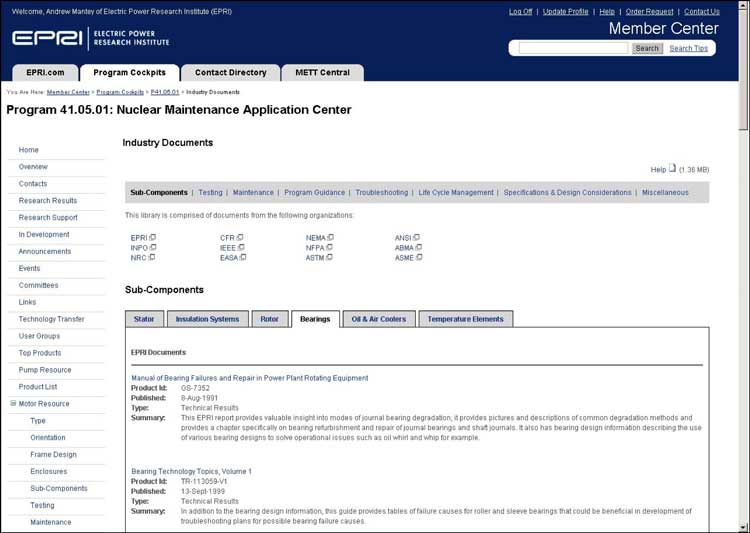

In September, the Motor Resource was rolled out on EPRI’s website. This comprehensive motor resource is a web application available on www.EPRI.com under the NMAC Program Cockpit (the easy button on the home page at www.EPRI.com). This application has been designed for use by experienced and novice motor specialists, as well as others interested in obtaining general or specific information on design, maintenance, life-cycle management, program development, testing, and troubleshooting of electric motors.

This web application was developed with the assistance of the Large Electric Motor Users Group (LEMUG) and with direct support from selected LEMUG members who served as the technical advisory group.

The site is designed to allow an experienced user to quickly identify EPRI products, Nuclear Regulatory Commission documents, and other industry documents (from organizations such as the American Society for Testing and Materials, the Electrical Apparatus Service Association, the Institute of Electrical and Electronics Engineers, and the National Electrical Manufacturers Association) using the Industry Documents tab. For example, if an EPRI member wanted to know what information was available for motor bearings, the member could pull up the subcomponent tab and select Bearings. The figure on the next page shows the resultant window that comes up. This page has six EPRI reports and more than 20 industry standards identified that contain information on bearings. Each entry provides the data source (EPRI, American Bearing Manufacturers Association, and so forth), the document name, and a link to obtain the document. Selecting an EPRI document will take the user to the www.EPRI.com download page for that document, and, if the user is eligible, the user can initiate a download. Industry documents are linked to the document provider’s home page for a user to obtain additional information on how to purchase a specific document.

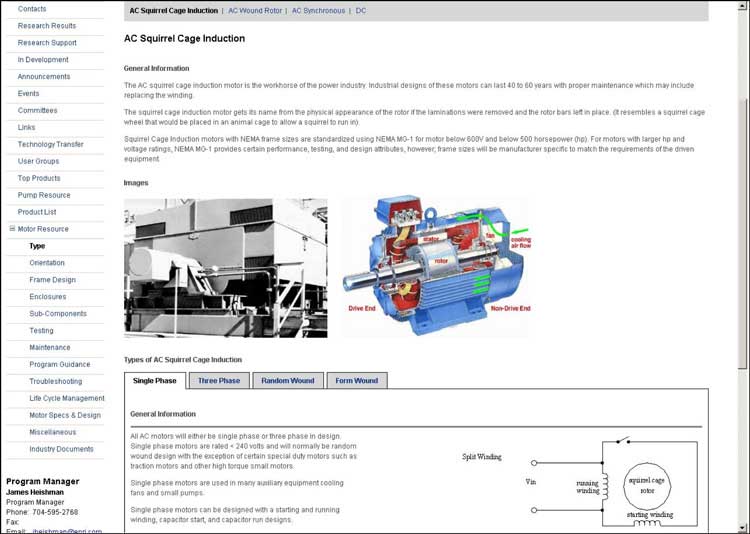

The Industry Documents webpage

Individuals with less experience can use the site as a learning tool on motor basics. Each topic has a short tutorial on the subject, pictures or diagrams, and a link to the industry documents page for that specific topic. The figure below is an example of a motor-type page shows some basic information on an ac squirrel cage induction motor.

The ac squirrel cage induction motor webpage

This web application is meant to be a living document that can be easily updated to include additional information. For example, new or revised EPRI reports and industry standards can be added by the NMAC project manager or through a request from users. A Contact Us link is also provided on the main page, and it allows the user to send an e-mail to the responsible NMAC project manager with ideas for additions or improvements to the web application.

The concept of this web application is to provide users an easier method to identify where information for a specific topic can be found and then accessed quickly, regardless of experience level. Additionally, it can be an educational tool for new engineers or maintenance personnel to learn motor basics and delve deeper into the voluminous quantity of EPRI products on motors in a more focused manner.

For more information, contact Andrew Mantey, 484.467.5864, amantey@epri.com.

KKL, EPRI Co-Sponsor First European Foreign Material Exclusion Workshop

This first Foreign Material Exclusion (FME) workshop was conducted October 4–6, 2011, and was sponsored by Kernkraftwerk Leibstadt (KKL) and EPRI. Andrew Barrit and Martin Buhler of KKL were instrumental in initiating and organizing this workshop. The primary objective of the FME workshop was to improve FME program performance in the nuclear industry. Debris contributes to a significant percentage of fuel failures. In addition to fuel failures, foreign material has resulted in failures to critical equipment and has reduced overall unit reliability. The workshop was held at the KKL Information Center, shown in the figure below.

The KKL Information Center

Similar workshops have been conducted in the United States for several years and can be directly credited for improving FME program performance in the United States.

The FME workshop provided a forum for the exchange of FME best practices, operating experience, and lessons learned with peer industry personnel responsible for the FME programs at their respective plants. Additionally, EPRI provided an overview of EPRI FME products that are currently available to NMAC members, as well as the status of new products in development.

Vattenfall offered to host the next European FME workshop in Sweden near the Ringhals power plant. The duration of the meeting will be two and one-half days, and the meeting will be scheduled in April or May 2012. After workshop details are finalized, notifications will be issued. The workshop will continue to be conducted in English, and non-EPRI members are welcome to attend.

Agenda items and topics planned for the next meeting are as follows:

- World Association of Nuclear Operations FME program evaluation results and available guidelines will be provided.

- Utilities attendees will be requested to provide information about several FME operating experience events.

- Additional electrical- and instrumentation and control-related FME issues and presentations will be solicited.

- FME program key performance indicators will be discussed.

- The International Atomic Energy Agency will provide a status of its FME guideline development.

For additional information about European FME workshops, contact Lee Rogers, 772.288.4369, rogers@epri.com.

Work Planning Managers/Supervisors Identify Key Issues and Prioritize Activities

EPRI hosted the Work Planning Users Group (WPUG) winter meeting January 26–28, 2011, at the EPRI offices in Palo Alto, California.

The WPUG goal is to improve maintenance effectiveness and equipment reliability by continuously improving the work planning departmental performance.

This initiative is providing consistent strategic and tactical standards by developing industry best practices and operating experience and by further defining and improving the process for work package quality, preparation, execution, and feedback.

Issues and Priorities

A portion of the meeting was reserved so that all attendees could discuss their site’s work planning challenges and accomplishments. This forum allows for the identification of common issues for the group to focus on, as well as good practices that can be shared among utilities. At the beginning of the meeting, the attendees listed and prioritized by vote the major issues confronting planning. The following is a prioritized list (1 being the highest priority) of the current major issues confronting planning organizations:

1. Work package quality/skill of the craft

2. Parts, difficult to find, obsolete, or dormant

3. Planner training

4. Planner resource management

4. Planner attrition, retirements

5. Craft to planner career path

6. Planning metrics

7. Planning quality review team process

7. Planning troubleshooting packages

7. Emergent work (new)

8. Outage scope changes (new)

9. Post-maintenance testing on critical equipment (new)

9. Late issuance of modifications (new)

9. Risk assessment by planning

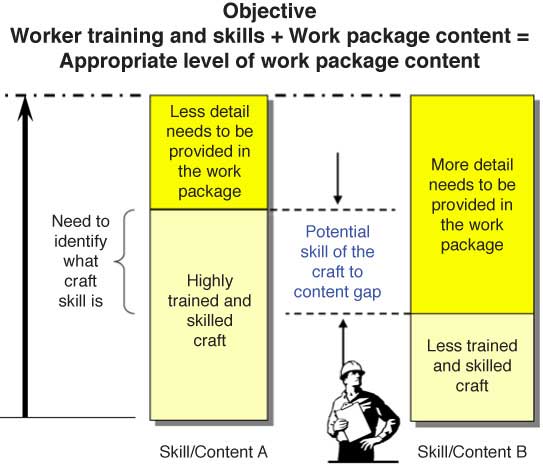

Work package quality and skill of the craft are closely related. Planning personnel must know what level of skill the craft has so that the planner can match the work instruction detail correctly to the craft skill level (see the figure below).

Comparing skill of the craft and work package detail

Institute of Nuclear Power Operations Update

Hank Nelson from the Institute of Nuclear Power Operations (INPO) provided a presentation that addressed the following topics:

- Overview of maintenance and work management areas for improvement (AFI) trends

- Work planning AFI trends

- Industry scram trends and analysis

- New industry guidance, INPO 11-003, Guidance for Excellence in Procedure and Work Instruction Use and Adherence, and Changes to AP-928, Work Management Process Description

Description

Nelson also informed the WPUG attendees that INPO will soon be issuing a Level 2 INPO event report that will require that certain corrective actions be defined within 120 days of the issue date. Some of the corrective actions, such as the following, will require action by planning:

- Perform an evaluation of work instruction and maintenance technical procedure detail (EPRI report 1011903, Maintenance Work Package Planning, is a reference).

- Conduct an assessment of station standards for procedure and work instruction use and adherence (a new industry guideline, INPO 11-003, was issued in June 2011).

- Evaluate station operational impact and risk programs.

Updating of EPRI Work Planning Guideline

EPRI report 1011903, Maintenance Work Package Planning Guidance, which was issued in December 2005, will be revised to address the more recent planning challenges, best practices, and new planning initiatives.

Specific areas that will be addressed in the new revision are the following:

- Work package quality, level of detail for work packages, and skill of the craft

- Planner clearance responsibilities

- Work package content for supplemental personnel

- Planner training and qualification

- Planner FME program responsibilities

- INPO AP 928 R3, Work Management Process Description, effects on planning

- Human factors procedure writing for planners

The target completion date for this revision is by year-end 2012.

Subcommittees were formed to facilitate specific areas for the development of this revision.

The winter WPUG will be Tuesday, Wednesday, and Thursday, January 31 through February 2, 2012, at the Hilton Garden Inn at PGA Village/Port St. Lucie, in Port St. Lucie, Florida. Follow the following link to register for the meeting: www.cvent.com/d/3cqmc9.

For more information about the WPUG and its activities, contact:

EPRI Project Manager Lee Rogers, 772.288.4369, lrogers@epri.com

WPUG Chairperson Steve Johnson (INL), StephenC.Johnson@inl.gov

WPUG Vice Chairperson Dale Shaw (Exelon), dale.shaw@exeloncorp.com

Circuit Breaker Users Group Update

The Circuit Breaker Users Group (CBUG) met in August 2011. The more prominent issues discussed during this meeting included the following:

- General Electric (GE) recommended performing low-resistance measurements on its Magne-Blast arc chutes. GE is considering an informational Service Advice Letter that covers arc chute testing/maintenance.

- Several plants have implemented additional maintenance tasks for model DS circuit breakers. These tasks pertain to inspection and replacement of switches and components that provide the interface between the DS breaker and the breaker cubicle. These tasks are described in the Westinghouse MPM maintenance manual for DS circuit breakers.

- Westinghouse agrees and supports the practice of disconnecting the cycle counter during maintenance of DS circuit breakers. This position is not contained in Westinghouse manuals or a technical bulletin, but rather can be provided on Westinghouse letterhead to individual utilities.

- Due to inquiries from the Nuclear Regulatory Commission, some plants are implementing additional testing for motor control center maintenance. This testing pertains to reduced/degraded voltage pickup and dropout testing.

- GE provided an updated list of GE Service Advice Letters on CD-ROM during the meeting.

- The Westinghouse MPM Manual for DB type circuit breakers has been revised.

EPRI has published a brief, Circuit Breaker Users Group, that describes the CBUG along with the primary issues that the group is working to address. The EPRI product number for this brief is 1021243, and it can be found on EPRI’s website (www.epri.com). During the 2011 meeting, the primary issues described in this document were reviewed and revalidated.

In 2012, EPRI and the CBUG are expected to continue efforts to revise guidance relating to electrical bus and cable maintenance and to develop guidance on motor control center maintenance.

EPRI plans to complete the Circuit Breaker Specialist Guideline in 2012. The objectives of this guideline include identifying knowledge and skill sets needed to establish and maintain a circuit breaker program and enhancing industry and site-specific training for persons responsible for circuit breakers.

All materials from the meetings, including results of the surveys, are posted on the CBUG EPRI collaboration website and the 2011 meeting website (under the EPRI Events Tab).

The CBUG will meet again June 4–8, 2012, in New Orleans, Louisiana. Monthly conference calls have been established for the CBUG. These calls typically occur on the third Thursday of the month.

For more information, contact Jim Sharkey, 704.595.2557, jsharkey@epri.com.

Improving Emergency Diesel Generator Performance

The industry has embarked on an initiative to improve the performance of emergency diesel generator (EDG) systems. This effort was initiated after Institute of Nuclear Power Operations (INPO) identified a declining trend of EDG reliability and availability. EPRI was requested to identify EDG issues and gaps and help the industry define what should be done to improve diesel generator system performance.

An EDG Issues meeting was held at Entergy July 6–7, 2011. During this meeting, it was resolved that the industry needed a cohesive, coordinated effort to improve EDG performance. This meeting helped identify critical issues, which include leaks, control system and relay failures, preventive maintenance implementation adequacy, and critical spare parts. It was at this meeting that EPRI was requested to coordinate an industry initiative.

Various EDG fleets, alliances, and owners groups have increased their efforts to identify ways to improve performance. INPO continues to perform review visits to evaluate emergency ac power systems in selected U.S. nuclear plants.

On August 31, 2011, the topic of EDG reliability was discussed at EPRI’s Equipment Reliability Action Plan Committee (ER APC). The ER APC concurred with the formation of a technical advisory committee. This committee would serve as the coordinating body to ensure a cohesive, coordinated effort. EPRI is preparing a roadmap that depicts EDG performance improvement activities of the utilities, INPO, Nuclear Energy Institute, EPRI, and the industry’s EDG owners groups. A technical advisory committee has been formed, consisting of industry EDG personnel, industry EDG owners groups, NEI, INPO, and EPRI.

For more information, contact Jim Sharkey, 704.595.2557, jsharkey@epri.com.

Japanese Reliability-Centered Maintenance–Condition-Based Maintenance Users Group Update

As a result of regulatory changes, Japanese nuclear utilities are collectively moving toward condition-based maintenance (CBM) programs. To assist in this effort, EPRI sponsors the Japanese Reliability-Centered Maintenance–Condition-Based Maintenance (RCM-CBM) Users Group.

In RCM-CBM group meetings, Japanese and invited international CBM experts share plant case histories to expand their knowledge base and highlight lessons learned. In addition, the group has formed working groups that meet separately to discuss specific technologies, including vibration analysis, oil analysis, and infrared thermography. The RCM-CBM group’s list of prioritized topics includes the following:

- Extending the scope of CBM

- Establishing and modifying acceptance criteria

- Collecting and learning from case histories and CBM examples

- Education, training, and qualification

- Obtaining management support

- Introduction of techniques other than vibration, infrared thermography, and oil analysis

- Developing databases for managing the results of CBM activities

EPRI is working to assist the group in addressing issues pertaining to acceptance criteria and moving from time-based maintenance to CBM.

The vast majority of Japanese nuclear plants are shut down as a result of the March 11, 2011, earthquake and resultant tsunami. Even with many plants currently in long-term shutdown, the RCM-CBM group’s mission is still considered to be valid, and the interest from Japanese utilities is still strong. The group held a meeting in October 2011. The focus at this meeting was equipment layup and long-term plant shutdown. Gary Boles of EPRI and Richard Peppin of Progress Energy provided presentations on these topics. Bryan Johnson of Arizona Public Service provided case studies on lubrication, and Steve Ciesla provided case studies on vibration.

To support this group, EPRI published 1022284, Developing Maintenance Decisions Through Systematic Use of Machine Vibration Data, in 2011. The paper was written by George D’Entremont of Pacific Gas & Electric. Nuclear News magazine featured this paper in its November 2011 edition. This paper suggests systematic steps by which machine casing vibration data can be used to create maintenance decisions at a nuclear electric generating station. The paper is, in part, a response to topics discussed during meetings conducted in Japan by EPRI with its Japanese members in May 2010. These discussions related to the use of systematic review and evaluation techniques that promote the most accurate maintenance decisions. A vibration analyst, confronted with a large and expanding vibration database, could be overcome with questions of where he or she should concentrate his attention and what actions he or she should take to ensure that important data are not ignored. This paper presents a distilling technique, which reduces information from an existing vibration database in a manner that yields necessary maintenance decisions. It is not the intent to present this as an EPRI-recommended approach. It is, instead, offered as an example of one such approach taken at a U.S. nuclear station.

Selected technology experts from U.S. and international utilities attend these meetings to provide an international exchange and share their programs, experience, methods, and case histories. In conjunction with these meetings, benchmarking trips to Japanese nuclear plant sites are attended by predictive maintenance program and technology experts from other countries.

Utility personnel interested in sharing successful programs or unique case studies should contact Jim Sharkey, 704.595.2557, jsharkey@epri.com.

For information or questions regarding this group and these EPRI initiatives, contact Jim Sharkey, 704.595.2557, jsharkey@epri.com.

NMAC Meetings

2012 Joint EDG Owners Group Conference

EPRI will conduct the Joint Emergency Diesel Generator Owners Group Conference July 17–18, 2012, at the Minneapolis Marriott City Center. The event will be coordinated with individual emergency diesel generator (EDG) owners group meetings to be held July 19–20. This event is co-sponsored by the U.S.-based EDG owners groups, including ALCO, Cooper-Bessemer, Enterprise, ESI-EMD, Fairbanks Morse, and the Diesel Fuel Oil Group. The objective of the joint EDG conference is to provide a forum for personnel who operate and maintain emergency diesel generators to share information, operational and maintenance experiences, problems and solutions, and techniques to improve EDG reliability and availability.

Individuals who would like to present a paper or presentation should contact Jim Sharkey, 704.595.2557, jsharkey@epri.com.

NMAC Holds Workshop for Vodo-Vodyanoi Energetichesky Reactor-Style Pressurized Water Reactors Members

The NMAC membership includes more than 300 of the 400-plus operating nuclear power plants in the world. These member plants include most styles of reactors. There are water-cooled reactors, heavy-water-cooled reactors, and gas-cooled reactors. NMAC has reviewed the material provided to the NMAC members to determine the applicability of the NMAC information to the various members. The applicability of the information can change based on the type or manufacturer of the reactor systems, the country that the power plant operates in, and the types of auxiliary equipment. This applicability has been evaluated to be approximately 85% for all reactor styles. The reason that many of the data are not applicable is that the material is specific to a single vendor or to a single reactor type.

The analysis also pointed out that, much of the time, the applicability could be improved by the simple task of NMAC staff meeting with the members and explaining the reason for the research, why it was done, what work group the research report was written for, and how the research is to be used. NMAC and Plant Engineering (PE) are privileged to have 10 Vodo-Vodyanoi Energetichesky Reactor- (VVER-) style pressurized water reactors at two companies (CEZ Group, Czech Republic, and Slovenske Elektrame, Slovakia) and four sites (Temelin Nuclear Power Plant [NPP], Dukovany NPP, Mochovce NPP, and Bohunice NPP) as members. Discussions with the plant staffs revealed that a workshop to help them understand how to use the technical reports from these programs was needed to ensure good utilization of the EPRI information. A workshop to accomplish these goals was held October 3–5, 2011, at the Dukovany NPP site in the Czech Republic. This workshop was attended by more than 35 technical staff members from the corporate offices of the two companies and the four power plant sites. The NMAC/PE Program personnel conducting the workshop were Marty Bridges (NMAC), Bo Clark (PE), and Vaclav Vyskocil (Member Services).

The workshop included extended discussions of the EPRI Preventive Maintenance Basis Database, cable aging, high-density polyethylene pipe, buried pipe, component classification, and equipment reliability. The members were engaged and challenged the EPRI staff many times. The result of the workshop was an improved understanding of the applicability of EPRI information and more engagement with the use of EPRI reports. Participants also gained understanding of the value of member communication activities, such as the NMAC hotline, NMAC/PE newsletters, NMAC/PE websites, PE computer-based training, and NMAC/PE users groups.

One of the significant action items that resulted from this workshop was that both EPRI and the member utilities took actions to be proactive in continuing the process of identifying the ways that EPRI information can be used by the VVER plants and to ensure that EPRI program managers (PMs) remember to request VVER member participation in the development of technical reports that are addressing issues applicable to the VVER power plants. Additionally, both the members and EPRI PMs will pursue venues that can provide continued direct interaction among the VVER plants and the EPRI staff.

For more information, contact Marty Bridges, 704.595.2672, mbridges@epri.com or Bo Clark, 704.595.2684, bhclark@epri.com.

Pump Users Group Meeting

The NMAC Pump Users Group (PUG) 2011 meeting was held in Portland, Oregon, August 8–11. Downtown Portland turned out to be an excellent choice by the PUG, providing many opportunities to enjoy Portland and Oregon sights and to tour the Sulzer facility.

The meeting again had a focus on training, with Monday dedicated to two separate workshop sessions in separate tracks: best efficiency point and pump hydraulics by Sulzer and lubrication with Jim Fitch of Noria Corp. Tours to the Sulzer repair facilities were also provided.

The Tuesday through Thursday portion of the PUG meeting covered several key issues, including the following:

- Alignment training with John Piowtrowski of Turvac

- Bearing cooling pump shaft breakage

- An update on the N9000 reactor coolant pump (RCP) seal at the Surry plant

- Testing of pump voiding at Hydro, Inc.

- Reactor heat removal pump vibration issues at South Texas

- RCP monitoring by Daya Bay Plant

- An update on advanced diamond coating R&D by EagleBrugmann

- Seal cut O-ring, testing of N9000, and failed power supply issues at Oconee

- Feedpump reliability improvements

- Testing large horizontal circulating water pumps using Robertson Technologies

- Piston pump experience at Public Service Electric & Gas

- Introduction and use of laser Doppler vibrometry

All of these presentations were placed on the PUG collaborative webpage and eventually on the NMAC PUG webpage and are available to download by logging in to www.epri.com, selecting Users Websites, scrolling down to Nuclear and Pump Users Group (PUG), and selecting the Meeting and Minutes button on the left.

The PUG members voted in the business session to plan a meeting in conjunction with Exelon Corp. at the Oakbrook/Lombard Embassy Suites Hotel in the Chicago, Illinois, area August 13–16, 2012. Also considered were potential meeting locations in Charlotte, North Carolina; Chattanooga, Tennessee; and Charleston, South Carolina. More information will be posted on the EPRI NMAC PUG website and through e-mails to all our PUG members.

For more information, contact Paula Foster, 972.556.6509, pfoster@epri.com , or Dave Dobbins, 704.595.2560, ddobbins@epri.com , or go directly to www.epri.com and search Events in Nuclear in August 2012. You do not need an EPRI ID or password to register for this meeting.

Annually, the PUG will provide a deliverable document containing the following key parts:

- PUG meeting presentations and training provided

- Selected hotline questions of high importance submitted to the PUG and all responses

- Look-ahead plans for upcoming meetings

For more information, contact Dave Dobbins, 704.595.2560, ddobbins@epri.com.

Terry Turbine Users Group Meeting

For 2012, the Terry Turbine Users Group (TTUG) will hold its 20th meeting in San Diego, California, and will join with the NMAC Combined Condition-Based Maintenance (CCBM) Users Group July 16–19, 2012, at the Crowne Plaza Hotel. The TTUG meeting will include the Boiling Water Rector Owners Group Meeting in the same hotel. The TTUG meeting focuses on sharing timely information from suppliers for Terry Turbine equipment and plant-operating experiences. The TTUG will discuss focused information coming from the Fukushima Daiichi plants and important changes in operations, including extended coping time. Dresser-Rand will present an update on its new replacement digital governor, including present and future planned installations.

For more information, contact Dave Dobbins, 704.595.2560, ddobbins@epri.com, or go directly to www.epri.com, and search Events in Nuclear in July 2012. You do not need an EPRI ID or password to register for this meeting.

For 2012, the focus areas include the following:

- An auxiliary feedwater reactor core isolation cooling (RCIC) high-pressure core injection breakout session

- (Tentative) bus trip to visit San Onofre Nuclear Generating Station (SONGS) and to see the new Dresser-Rand auxiliary feedwater digital controls upgrade completed in 2011

- Selected hotline questions, as follows:

- Boroscopic inspection versus full teardown on 6- to 12-year basis

- Steam admission valve leakage

- Mechanical overspeed issues

- Trip and throttle valve leakage across seat

- Barriers to extended operations of Terry Turbines and how to correct them

- Digital controls replacement roundtable discussion, including the following:

- Support on aging controls

- Dresser-Rand review status of installations

- SONGS installation and results

- Farley installation and results

- Clinton plans for RCIC

- Advanced controls demonstration by ESI of new Woodward 505

- Developing your plant goals for Institute of Nuclear Plant Operations upper-quartile discussion session

- Training tour of NMAC and TTUG websites

- Pooled inventory management and plants spares for TTUG

All presentations will be made available to download by logging into www.epri.com, selecting Users Websites, scrolling down to Nuclear and Terry Turbine Users Group (TTUG), and selecting the Meeting and Minutes button on the left.

The workshops and meetings have been well attended over the years, and the reviews for the hands-on training have been very high because everyone wants to learn from the masters.

Annually, the TTUG will provide a deliverable document containing the following key parts:

- TTUG meeting presentations and training provided

- Updates as needed for the TTUG maintenance guides, especially as the controls are replaced with the new digital system design(s) and/or operating experience is added to the maintenance guides

- Selected hotline questions submitted to the TTUG of high importance and all responses

- Look-ahead plans for the upcoming meetings

The TTUG will also continue to employ an outside expert to consult on generic issues for the overall TTUG, not for the benefit of one plant.

Multimedia Training Modules for 2012

During the 2010 four-day intensive Terry Turbine training, NMAC hired a professional camera operator to record most of the training sessions. These recordings could lead to a major change in the training approach for the TTUG, which includes the following: continuing to support the needs of the TTUG as the skill level shifts and as the training needs may be shifted to an outside company, and developing multimedia Terry Turbine training modules for our members with a greater emphasis on computers and video and less emphasis on manuals. A sample of the training class was digitally recorded by a professional camera operator, and a sample video is on www.youtube.com—search NMAC TTUG, and click on it (the sample video runs 8 minutes). Anyone interested in being on the technical advisory group for these training modules should contact Dave Dobbins, 704.595.2560, ddobbins@epri.com.

For more information, contact Dave Dobbins, 704.595.2560, ddobbins@epri.com.

2011 Transformer and Switchyard Users Group Meeting

The Transformer and Switchyard Users Group (TSUG) meeting continues to be fortunate to have presentations from noted industry experts and dedicated equipment users. The meeting was held July 19–21 in Atlanta, Georgia, to facilitate a circuit breaker workshop on the Monday preceding the meeting. A session to review the status of the EPRI Transformer Handbook (Copper Book) was held July 21 and 22.

A 230/115-kV, 300-MVA transformer

Used with permission from Georgia Tech's National Electric Energy Testing Research and Applications Center (GaTech NEETRAC)

Dr. Poorvi Patel of ABB presented two fairly new testing methods being used in the industry for testing transformer condition—dielectric frequency response (DFR) analysis and sweep frequency response analysis (SFRA). These methods represent state-of-the-art testing for transformer insulation. DFR is used for determining moisture in transformer insulation, and SFRA is used to determine whether there has been coil or winding movement.

Dr. Michel Duval (inventor of the Duval triangle) updated the group on developments being made in dissolved gas analysis and monitoring, which is the primary method for determining the condition of transformer insulation. Duval’s presentation provided the attendees with insight into the changes being proposed for gassing levels being used by various industry standards, such as the Institute of Electrical and Electronics Engineers and International Electrotechnical Commission/Conference Internationale des Grandes Reseaux Electriques.

The Institute of Nuclear Plant Operations (INPO) has been conducting assessments of nuclear power plant transformer and switchyards since 2004. An update of its resent findings, such as gaps from INPO 09-008 responses, scrams related to transformer and switchyard events, and responses to Significant Operating Experience Report 10-1, was presented at the TSUG meeting. Shawn Simon of INPO also discussed transformer, switchyard, and data requirements for grid performance indicators.

Many nuclear plants are in the process of replacing large power transformers. Bill Hestir of Duke Energy shared his experience with replacing a reserve auxiliary transformer at Oconee station. This presentation provided some pointers for securing a transformer at the factory for site acceptance.

To support the acquisition of new transformers, factory testing is quite important. Kirk Robbins (from Exelon and the current TSUG chair) made a presentation that provided insight into monitoring in-process factory testing of large power transformers.

Because it has been years since some plants have replaced a large transformer, there is considerable effort required to accommodate the removal and installation of large power transformers. A presentation on an available software tool that can be used to aid in the process of moving transformers was provided at the meeting.

There is a looming issue in the industry related to the potential impact of forecast solar storms on large power transformers. It is being reported that these storms could produce high levels of geomagnetically induced currents (GICs). Dr. Ramis Girgis of ABB prepared a presentation that discussed their position on the effects of GICs on power transformers, factors that determine the magnitude of GICs, and available means of mitigating the effects of GICs.

During the meeting, Luke Van der Zel and Bhavin Desai provided an update of R&D work by the EPRI Power Delivery Group related to transformer and switchyard equipment. Also, Frank Rahn of EPRI, who tracks the number of loss of offsite power (LOOP) events in the nuclear industry, provided an update to the group on recent industry LOOP events and provided a perspective on external events that contribute to LOOPs.

The North American Electricity Reliability Corporation (NERC) has been undergoing an intense process to rewrite and review many of its standards. Bill Duge (First Energy), chair of the TSUG Grid Reliability Working Group, provided an update to the attendees related to several NERC standards that they should be aware of because of their potential impact on plant operating voltage.

Because frequency response analysis (FRA) has become an accepted tool for monitoring transformers, there have been efforts to develop an on-line tool to perform FRA. Larry Coffeen (GaTech NEETRAC) provided a presentation that discussed a field demonstration of the on-line FRA technology.

Surge arresters and insulator integrity are important to equipment protection and ground protection. To ensure component integrity, a presentation on new testing methods for the evaluation of metal oxide varistor lightning arresters and polymer insulators was provided by Jim McBride of JMX Services.

The planning for the 2012 TSUG meeting is in process. If you have a topic that you would like to present or an issue that you would like to see addressed during this meeting, contact Wayne Johnson at wejohnson@epri.com.

For more information, contact Wayne Johnson, 704.595.2551, wejohnson@epri.com.

Transformer and Switchyard Users Group Circuit Breaker Workshop

Although the first letter in TSUG stands for transformer, the Transformer and Switchyard Users Group (TSUG) has often held workshops on other switchyard components, such as bushings and insulators. The 2011 workshop was dedicated to high-voltage circuit breakers similar to the 800-kV breakers shown in the figure below.

SF6 dead tank 800-kV Breaker

Used with permission from HVB

The workshop was presented by Ben Bufi of HVB AE Power Systems and provided an overview of the types and performance characteristics of circuit breakers that one would encounter in a typical generating station switchyard or substation. Switchyard circuit breakers tend to be rated at voltage levels of 52 kV or above. The workshop covered circuit application configurations, interruption theory, condition assessment practices, general maintenance, and consideration for making refurbishment or replacement decisions.

The workshop was divided into four sections describing circuit breaker operation, operating mechanisms, interrupters, and supporting equipment, such as compressors.

The overall purpose of a circuit breaker—to provide a means for controlling the connection and disconnection of components in an electrical power system—was explained during the workshop. The presentation covered the factors necessary to extinguish an arc, such as velocity of the operating mechanism, distance of the contacts, arc cooling/quenching, current zero, and dielectric strength of breaker medium (oil, air, vacuum, or gas).

After the presentation portion of the workshop, the attendees toured the HVB AE Power Systems breaker manufacturing facility. The facility primarily manufactures circuit breaker operators that use either SF6 or vacuum interrupters.

For more information about this workshop, contact Wayne Johnson, 704.595.2551, wejohnson@epri.com.

Pressure Relief Device Interest Group—Update and Status

The Pressure Relief Device Interest Group’s annual meeting will be held January 16–18, 2012, in Orlando, Florida. This meeting will be located at a new venue, Rosen Plaza on International Drive, a short distance from our previous location. We have been fortunate for the past two years to have experienced a very good attendance despite a difficult economy, and we hope this support will continue from our membership.

Tentatively, we have some interesting topics on the agenda. They are as follows:

- Update of in situ testing

- Pressurizer safety valve challenges

- Solenoid power–operated valve issues—boiling water reactors (BWRs)

- Testing and maintenance cycles of moisture separator reheater pressure relief valves (PRVs) with emphasis on pilot-operated valves (PORVs)

- Nuclear Electric Insurance, Ltd.

- PRV test intervals

- Canadian deuterium/uranium plants—PRV test intervals

- Operating experiences—discussions, future impact, and so forth

- Dikkers main steam safety valves for BWRs

- Temperature measurements Target Rock PORVs at Quad Cities and Dresden

We are planning to discuss the possibility of a change in the meeting structure for those held after 2012. This will be one of the topics we review on Wednesday morning, January 18. We will ask the membership to vote on whether to maintain the current arrangements or to adopt a meeting format similar to the Air-Operated Valve Users Group and the Motor-Operated Valve Users Group. We plan an open discussion with the membership on this issue.

Also, our operating rules require a nomination and election this January for chair, vice chair, and secretary for a two-year term.

Needless to say, we are all hoping for comfortable weather at the upcoming meeting.

For more information, contact Bob O’Neill, 508.539.3301, roneill@epri.com.

2012 NMAC Meetings

| Users Groups | ||||

| Meeting | Date | Location | Contact | Phone |

| Pressure Relief Device Interest Group | January 16–18, 2012 | Orlando, FL | Bob O’Neil | 508.539.3301 |

| Large Electric Motor Users Group/WS | January 30–February 2, 2012 | New Orleans, LA | Wayne Johnson | 704.595.2551 |

| Work Planning Users Group | January 31–February 2, 2012 | St. Lucie, FL | Lee Rogers | 772.288.4369 |

| Maintenance Rule Users Group/WS | February 14–16, 2012 | San Antonio, TX | Marty Bridges | 704.595.2672 |

| Japanese RCM-CBM Users Group | May 2012 | Japan | Jim Sharkey | 704.595.2557 |

| Circuit Breaker Users Group | June 4–8, 2012 | New Orleans, LA | Jim Sharkey | 704.595.2557 |

| Hoisting, Rigging, and Crane Users Group | June 18–22, 2012 | TBD | Merrill Quintrell | 704.595.2530 |

| Terry Turbine Users Group | July 16–19, 2012 | San Diego, CA | Dave Dobbins | 704.595.2560 |

| Combined Condition Based Maintenance (PdMUG/IRUG/VTF/Lube and Bearing) |

July 16–20, 2012 | San Diego, CA | Tom Turek | 484.631.5863 |

| Work Planning Users Group | July 2012 | TBD | Lee Rogers | 772.288.4369 |

| Transformer and Switchyard Users Group | July 2012 | TBD | Wayne Johnson | 704.595.2551 |

| Preventive Maintenance Basis Database Users Group/WS | TBD | Charlotte, NC | Marty Bridges | 704.595.2672 |

| Maintenance Rule Users Group | TBD | TBD | Marty Bridges | 704.595.2672 |

| Pump Users Group/WS | Second week of August 2012 | Oakbrook, IL | Dave Dobbins | 704.595.2560 |

| Large Electric Motor Users Group | August 2012 | TBD | Wayne Johnson | 704.595.2551 |

| Japanese RCM CBM Users Group | October 2012 | Japan | Jim Sharkey | 704.595.2557 |

| Japanese Valve Users Group | November 2012 | Japan | Nick Camilli Bob O’Neil |

704.595.2594 508.539.3301 |

| Workshops | ||||

| Meeting | Date | Location | Contact | Phone |

| Large Electric Motor Workshop | January 30, 2012 | New Orleans, LA | Wayne Johnson | 704.595.2551 |

| Outage Management Workshop (joint meeting with INPO) | Week of January 30, 2012 | Atlanta, GA | Gary Boles | 704.595.2781 |

| Maintenance Rule Workshop | February 14, 2012 | San Antonio, TX | Marty Bridges | 704.595.2672 |

| Hoisting, Rigging, and Crane Users Group Workshop | June 2012 | TBD | Merrill Quintrell | 704.595.2530 |

| Preventive Maintenance Basis Database Workshop | TBD | Charlotte, NC | Marty Bridges | 704.595.2672 |

| MOV-PPM Training | July 2012 | Charlotte, NC | John Hosler | 704.595.2720 |

| Terry Turbine Users Group Workshop | TBD | TBD | Dave Dobbins | 704.595.2560 |

| Transformer and Switchyard Workshop | July 2012 | TBD | Wayne Johnson | 704.595.2551 |

| Pump Workshop/UG | Second week of August 2012 | Oakbrook, IL | Dave Dobbins | 704.595.2560 |

| Large Electric Motor Workshop/UG | August 2012 | TBD | Wayne Johnson | 704.595.2551 |

| Other Meetings/Conferences | ||||

| Meeting | Date | Location | Contact | Phone |

| Joint Emergency Diesel Generator Owners Group Conference | July 17–20, 2012 | Minneapolis, MN | Jim Sharkey | 704.595.2557 |

| Steering Committee Meetings | ||||

| Meeting | Date | Location | Contact | Phone |

| NMAC Integration Committee Meeting | February 2012 | TBD | Jim Heishman | 704.595.2768 |

| NMAC Integration Committee Meeting | August 2012 | TBD | Jim Heishman | 704.595.2768 |

| NMAC Japanese Technical Advisory Committee Meeting | October 2012 | Japan | Jim Heishman | 704.595.2768 |

| NMAC European Technical Advisory Committee Meeting | TBD | TBD | Jim Heishman | 704.595.2768 |

| Recurring NMAC Meetings | ||||

| Meeting | Recurring | |||

| Pressure Relief Device Interest Group | Third week of January | |||

| Work Planning Users Group | January and July | |||

| Large Electric Motor Users Group | January and August | |||

| Maintenance Rule Users Group/WS | February and August | |||

| Japanese RCM-CBM Users Group | May—week before Memorial Day | |||

| Rod Control System Users Group | Second or third week of June | |||

| Hoisting, Rigging, and Crane Users Group | Second or third week of July | |||

| Combined Condition-Based Maintenance (PdMUG/IRUG/VTF/Lube and Bearing) |

Second full week of July | |||

| Terry Turbine Users Group | Second week of July | |||

| Transformer & Switchyard Users Group | July | |||

| Preventive Maintenance Basis Database Users Group | Second week of August | |||

| Circuit Breaker Users Group | TBD | |||

| Pump Users Group/WS | Normal second week of August; when LEMUG & PUG join, third week of August | |||

| NMAC Integration Committee Meeting | Summer Meeting—First full week after Labor Day | |||

| Japanese RCM-CBM Users Group | Third week of October | |||

| Japanese Valve Users Group | Last week in October | |||

| NMAC Integration Committee Meeting | Winter Meeting—second week after NPC Meeting | |||

| NMAC Japanese Technical Advisory Committee Meeting | Last week in October | |||

NMAC Members and Personnel

NMAC Domestic Membership

- AmerenUE

- American Electric Power

- Arizona Public Service

- Constellation

- Detroit Edison

- Dominion Energy

- Duke Energy

- Energy Northwest

- Entergy

- Exelon

- First Energy

- Florida Power & Light

- INL (NA)

- Knolls Atomic Power Labs (KAPL)

- Luminant

- Nebraska Public Power

- NNSA Oak Ridge (ORNL)

- Omaha Public Power

- Pacific Gas & Electric

- PPL Susquehanna

- Progress Energy

- Public Service Electric & Gas

- South Carolina E&G

- South Texas Operating Co.

- Southern California Edison

- Southern Nuclear Operating Co.

- Tennessee Valley Authority

- Wolf Creek

- Xcel Energy Services

NMAC International Membership

- Almaraz (Spain)

- Asco (Spain)

- British Energy (UK)

- Bruce Power (Canada)

- Cernavoda (Romania)

- CEZ (Czech Republic)

- CFE (Mexico)

- Chubu (Japan)

- Chugoku (Japan)

- Cofrentes (Spain)

- Daya Bay (China)

- Electrabel (Belgium)

- Electricité de France

- Electronuclear (Brazil)

- Eskom (South Africa)

- Hokkaido (Japan)

- Hokuriku (Japan)

- Hydro Quebec

- JAPCO (Japan)

- J-Power (Japan)

- Kansai (Japan)

- KHNP (Korea)

- KRSKO (Slovenia)

- Kyushu (Japan)

- Leibstadt (Switzerland)

- NASA (Argentina)

- New Brunswick (Canada)

- Ontario Power (Canada)

- Santa Maria De Garona (Spain)

- Shikoku (Japan)

- Slovenske Electrarne (Slovakia)

- Taiwan Power

- TEPCO (Japan)

- Tohoku (Japan)

- Trillo (Spain)

- Vandellos (Spain)

NMAC Personnel

| Name | Title | Phone | Coverage Area | |

| Gary Boles | Consulting Employee | 704.595.2781 | gboles@epri.com | Mechanical components, component engineering, maintenance processes, work planning |

| Marty Bridges | Sr. Project Manager | 704.595.2672 | mbridges@epri.com | Preventive maintenance programs, preventive maintenance basis database, equipment reliability, maintenance assessments, condition-based maintenance programs, main condensers, maintenance engineering |

| Nicholas Camilli | Sr. Project Engineer/Scientist | 704.595.2594 | ncamilli@epri.com | Lubrication, mechanical support, valves and bolting, power uprates |

| Lee Catalfomo | Sr. Project Manager | 813.996.3357 | lcatalfo@epri.com | Equipment reliability, maintenance process improvement, operations support |

| Dave Dobbins | Sr. Project Manager | 704.595.2560 | ddobbins@epri.com | Pumps, Terry Turbines |

| Alan Grunsky | Sr. Program Manager, NSTI | 704.595.2556 | agrunsky@epri.com | Nuclear Steam Turbine Initiative |

| Jim Heishman | Program Manager, NMAC | 704.595.2768 | jheishman@epri.com | Maintenance, engineering, operations |

| Wayne Johnson | Sr. Project Manager | 704.595.2551 | wejohnson@epri.com | Electrical components, electrical systems, motors |

| Bob O’Neill | Consulting Employee | 508.539.3301 | roneill@epri.com | Valves: MOVs, SOVs, PRVs, AOVs |

| Mike Pugh | Consulting Employee | 919.812.5162 | mpugh@epri.com | Condensers, circulating water systems, mechanical components, lubrication |

| Merrill Quintrell | Sr. Project Manager | 704.595.2530 | mquintrell@epri.com | Hoists, rigging, and cranes |

| Lee Rogers | Sr. Project Manager | 772.288.4369 | lrogers@epri.com | Maintenance processes, work planning, foreign material exclusion, power uprates |

| Deborah Rouse | Sr. Administrative Assistant | 704.595.2520 | drouse@epri.com | Program administration |

| Jim Sharkey | Sr. Project Manager | 704.595.2557 | jsharkey@epri.com | Circuit breakers, main generators, emergency diesel generators |

| Tom Turek | Sr. Project Manager | 484.631.5863 | tturek@epri.com | CBM with a focus on rotating equipment |

| David Ziebell | Sr. Project Manager | 404.316.9823 | dziebell@epri.com | O&M processes and practices, clearance and tagging, change management |

| NMAC HOTLINE Contact the NMAC hotline if you need any further assistance. Email address: nmachotline@epri.com Toll free number: 800.356.7448 – option 2 Your request will be responded to in one to two business days. |