| Building on proven success in mitigating corrosion product fouling in recirculating steam generators, dispersant injection is now being applied successfully during long-path recirculation cleanup and steam generator wet layup.

The use of dispersants in pressurized water reactors (PWRs) has been extensively qualified by EPRI over the past decade in multiple applications. Building on demonstrated success for reducing corrosion product fouling in recirculating steam generators, dispersant injection has more recently been qualified for application during the post-outage long-path recirculation cleanup period (EPRI Report 1019237, Dec. 2009) and during steam generator wet layup (EPRI Report 1022826, June 2011).

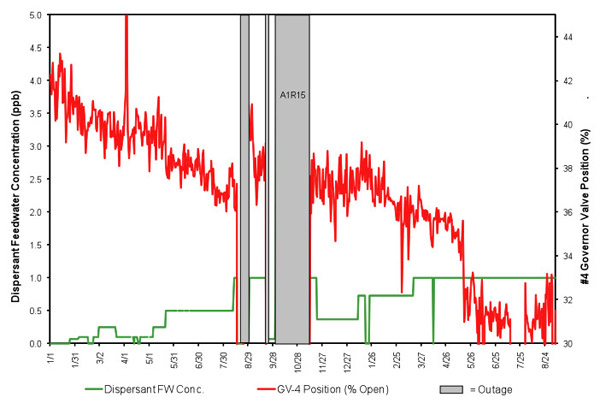

Exelon and STP Nuclear Operating Company have implemented online dispersant technology at six PWR units with recirculating steam generators to reduce corrosion product fouling. The result has been an increase in steam generator steam pressure and an improvement in the margin to turbine valves-wide-open. For example, Exelon has been able to close the #4 turbine governor valve at Braidwood Unit 1 by about 10% of travel since initial dispersant injection (see figure). On-line dispersant application also has improved steam generator iron removal efficiency, reducing the steam generator fouling rate. Online application is expected to begin at international units later in 2011, including Doel 3 in Belgium and Golfech 2 in France.

Dispersant application during the long-path recirculation cleanup period can reduce the amount of corrosion products available for transport to the steam generators by more effectively flushing the condensate and feedwater systems prior to initiating flow to the steam generators. A first application occurred at Byron 1 in Spring 2011 under EPRI sponsorship. "The application demonstrated that dispersants are an effective tool to manage the effects of iron transport during non-operational periods and startups, and eliminated the Chemistry Effectiveness Indicator penalty for Byron 1 that has been challenged by iron transport problems during startup," said Dave Morey, Senior Chemistry Specialist, Exelon Nuclear. Exelon plans the next application at Byron 2 this Fall.

EPRI also has qualified dispersant application for steam generator wet layup chemistry to remove some of the existing corrosion product inventory from the steam generators. A field application at Three Mile Island in Fall 2009, along with field applications at Doel 3 in Summer 2010 and Braidwood 1 in Fall 2010, demonstrated the effectiveness of this application. In addition to iron removal, the applications consistently increased removal of hardness elements (i.e., calcium, magnesium and aluminum) that contribute to the formation of hard sludge collars.

Finally, in 2011, EPRI began a two-year revision process of the dispersant application sourcebook, which was initially published in 2007 as EPRI report 1015020. The revised sourcebook will include updated guidance for online applications (including lessons learned from the current applications), as well as guidance and recommendations for dispersant application during long-path recirculation cleanup and steam generator wet layup.

For more information, contact Keith Fruzzetti at 650.855.2211 or kfruzzet@epri.com.

Increased margin to valves-wide-open (as demonstrated by approximately 10% closure of the #4 turbine governor valve) at Braidwood Unit 1 with Online Dispersant Application

|