| The use of computer modeling and simulation could improve the reliability of nondestructive evaluation techniques and reduce the need for expensive physical development and testing.

Utilities and inspection vendors often spend a significant amount of resources in the development, assessment, and demonstration of nondestructive

evaluation (NDE) techniques, which are used to assess the integrity of power plant components. Regulatory and industry commitments require validated

solutions, but traditional approaches to validation are costly and time-consuming. EPRI is developing an NDE modeling and simulation center that could

replace or augment physical development and testing. Successful deployment of these capabilities would result in more reliable and efficient

examinations, potentially leading to reduced overall inspection costs.

Collaboration will play a major role in this research. NDE modeling and simulation efforts at utilities and other organizations will be used to complement EPRI activities. Research and development agreements also could be used to perform NDE simulations of the modeled results with experiments. EPRI can share its representative component mockups, NDE equipment, and experienced staff to support the physical validation of models. Finally, the software and personnel acquired for the modeling and simulation center could serve as third-party validation for simulation tools of outside organizations.

NDE inspection procedures must be demonstrated before use on safety-related components. Representative mockups for technique development and

qualification are used for this purpose, but can cost $100,000 to $1 million each and take years to build. Failed empirical trials can also impact cost

and inspection schedules. Modeling and simulation can be used to offset these cost and scheduling concerns. For example, EPRI has developed

three-dimensional computer modeling technology for designing ultrasonic procedures for nozzle inner radius and nozzle-to-shell weld examinations.

Ongoing training is important in ensuring NDE technicians are prepared to conduct nuclear NDE inspections and evaluate any indications. Computer-based

training courses generated through EPRI's modeling and simulation center will assist in explaining complex inspection challenges, using practical and

realistic examples. These courses also may help bring new personnel into the industry, narrowing the NDE workforce gap.

NDE techniques sometimes require a probability of detection (POD) for condition assessment and as an input into larger probabilistic models to evaluate

component inspection frequencies. Whereas physical demonstration often includes personnel testing to establish inspection system capability in terms of

POD, modeling and simulation can predict those results in lieu of costly performance demonstration testing.

Finally, EPRI has used modeling and simulation to design ultrasonic probes and related inspection procedures for nozzle and piping examinations. With

the expected capabilities of the modeling and simulation center, EPRI plans to broaden its capabilities to a wider range of applications, including the

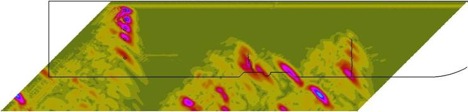

use of commercial NDE packages and the development of new software. The example below illustrates the use of Wave3000™ and MATLAB® to

predict the ultrasonic responses obtained from a reference block containing side-drilled holes and simulated cracking. Such software can be used in

modeling different characteristics to determine the optimum ultrasonic transducer parameters for an inspection.

For more information, contact Mark Dennis at 704.595.2648 or mdennis@epri.com.

|

|

|

Example of Ultrasonic Defect Responses from Reference Reflectors (Generated with Wave3000™ developed by Cyberlogic®, Inc and processed in

MATLAB® developed by MathWorks® for data reconstruction) |

|