| Plant data from eight units helped develop the preliminary model, which revealed strong correlations between blockage and parameters such as feedwater iron and copper concentrations and the unblocked flow area.

The iron-based corrosion products generated in the secondary systems of pressurized water reactors are primarily deposited on steam generator tube heat-transfer surfaces. In steam generator designs with broached-hole tube support plates, a small fraction of the corrosion-product material can deposit within the flow holes in the tube support plates, gradually blocking the available flow area. Accumulation of these deposits can cause multiple difficulties, including thermal-hydraulic instability manifested as liquid level oscillations, tube fatigue caused by flow-induced vibration, and reduced thermal efficiency.

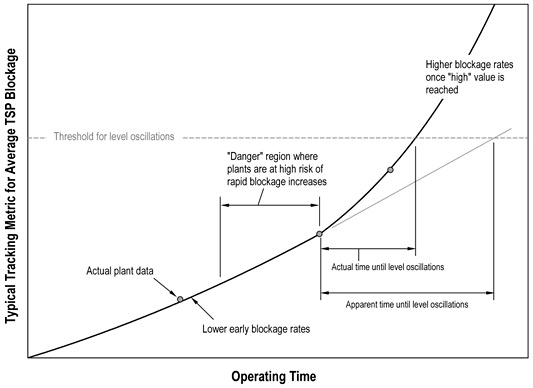

Experience shows that blockage speeds up over time. Basically, as the opening begins to get blocked, the rate of blockage increases – even for steam generators that have exhibited only modest increases in blockage in the past. The accompanying figure illustrates how using historical changes in blockage to project future blockage might suggest a longer period of safe operation than actually exists. A tool that could predict the progression of deposit blockage would enable nuclear plants to better gauge the risk of severe blockages and, if necessary, plan for deposit removal with plenty of time margin.

EPRI's Steam Generator Management Program is developing an empirical model for predicting broached-hole blockage caused by deposit accumulation. The preliminary model is based on plant data from eight units. The model relates changes in blockage to independent parameters such as steam generator geometry and feedwater characteristics, and employs conventional and probabilistic methods to account for uncertainties in the inputs and the model.

The model reveals strong correlations between the rate of tube support plate blockage and four independent plant parameters: the prevailing blockage fraction, feedwater iron concentration, feedwater copper concentration, and the nominal (unblocked) broached-hole flow area. These correlations are supported by industry experience and theoretical considerations. Refinement of the statistical model with data from additional units is underway and will facilitate future model application for making reliable quantitative blockage predictions for actual units.

EPRI Report 1022667, Empirical Model for Predicting Recirculating PWR Steam Generator Broached-Hole Blockage, contains a description of the model, examples showing how the model can make predictions for a set of representative plant parameters, and an evaluation of the chance that at least one unit in a sample susceptible group will experience severe blockage.

For more information, contact Heather Feldman at 704.595.2735 or hfeldman@epri.com.

Qualitative Progression of Observed Broached-Hole Blockage Increases

|