| Using data from about 100 operating cycles at both pressurized and boiling water reactors, the analysis characterizes feedwater iron transport differences and identifies trigger points for more detailed analysis.

Nuclear plant owners are showing greater interest in corrosion product transport during startups because of a renewed emphasis on minimizing total transport during the normal operating cycle. Limiting corrosion product transport can reduce fuel deposition, the tendency for hot spot formation in boiling water reactors (BWRs), and surface fouling and aggressive chemical solution formation in partially occluded regions of steam generators in pressurized water reactors (PWRs).

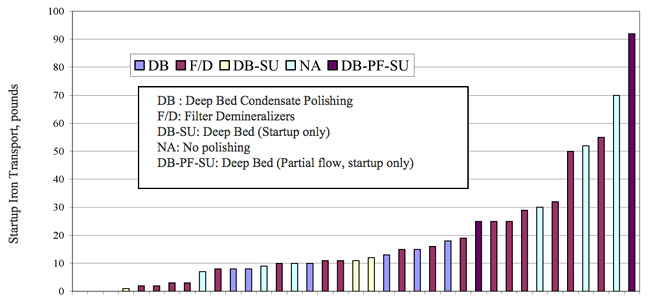

Using plant data from about 100 operating cycles, EPRI quantified feedwater iron transport during startups and evaluated its effect on total transport during a normal operating cycle. The study also assessed the effectiveness of current approaches to minimizing transport during startups, including feedwater and condensate system layup, and flushing and cleanup during recirculation. Some of the major findings from the analysis include:

Startup feedwater iron transport at PWRs was significantly greater than at BWRs, even though full-flow condensate treatment was available for cleanup at many of the PWR sites that exhibited significant transport.

- Startup feedwater iron transport at BWRs was minimal, at less than about 10 pounds for all of the cycles considered.

- The difference in startup feedwater iron transport between BWRs and PWRs is likely due to the transition from a highly reducing to a highly oxidizing environment during PWR shutdown, compared to the stable oxidizing environment during BWR shutdown. The transition phase in PWRs leads to a destabilization of the oxides and increased startup feedwater iron transport.

- Although several EPRI reports include detailed information on approaches to wet layup for steam, feedwater and condensate system piping and components, implementation of such practices is not common at nuclear plants due to short outages and resource requirements. The obvious exception is for PWR steam generators, for which wet layup is required by the EPRI Secondary Water Chemistry Guidelines.

- A survey of approximately 20 BWR plants indicated no observations of component corrosion associated with layup program deficiencies over the last 10 years.

The EPRI study, detailed in technical report number 1021112, Corrosion Product Transport during Boiling Water Reactor and Pressurized Water Reactor Startups, recommends that nuclear plants routinely evaluate startup transport using the techniques employed in the study. The study also recommends that if startup transport to the PWR steam generators or BWR reactor pressure vessel exceeds a site specified value, typically about 20 pounds, more detailed studies should be considered to identify transport sources and possible approaches to reducing transport during future startups.

For more information, contact Keith Fruzzetti at 650.855.2211 or kfruzzet@epri.com.

PWR Startup Iron Transport Based on 37 Cycles of Data from Various Plants

|