| EPRI is working with the Nuclear Regulatory Commission's Office of Research to assess the continued use of remote visual examination for reactor

pressure vessel internal components.

The nuclear industry relies heavily on the use of remote visual examination (VT) for assessing reactor pressure vessel internals and related

components. Global regulators, however, have questioned its reliability. Some European regulators, for example, have implemented procedure and

personnel qualification requirements for remote VT, and the Nuclear Regulatory Commission (NRC) is considering such requirements for the U.S. nuclear

power industry.

Implementing such requirements could result in high initial costs for training and qualification, and could increase inspection time, radiation dose,

and outage duration. Because the quantitative reliability of remote VT is not well understood or documented, EPRI is engaged in several efforts to

inform regulatory and industry decisions.

| |

|

| |

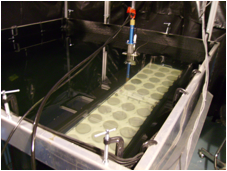

Round-robin test tank with specimens |

First, at NRC's invitation, EPRI is coordinating industry collaboration in a three-phase round-robin study that will evaluate the reliability of remote

VT. Phase 1, performed at EPRI's laboratory facilities in Charlotte, NC, consisted of four teams examining flawed test specimens fabricated by Pacific

Northwest National Laboratory (see photo). The results from Phase 1 did not reveal any immediate issues with remote VT's flaw detection capabilities

and are being used to plan a Phase 2 round-robin test scheduled for 2012. Second, EPRI is providing technical support to two non-U.S. members as they

work to comply with a new regulatory requirement for remote VT procedure and personnel qualification. This experience will be useful in informing

implementation in the United States and elsewhere if qualification requirements are imposed.

Specific activities being conducted through these two projects include:

-

Parametric studies of remote VT process variables and their relationship to flaw detection reliability

-

Development of refined flaw design and fabrication processes for remote VT test specimens

-

Identification of technology gaps, improved remote VT processes, and alternatives to remote VT

-

Development of flaw acceptance and evaluation criteria

-

Benchmarking of global remote VT technology and research activities, including technical support of reliability studies and qualification

programs

For more information, contact John Lindberg at 704-595-2625 of jlindberg@epri.com.

|