| Finite element analysis demonstrates that weld overlays can be applied to areas up to 1000 square inches without generating unacceptable stress levels.

As nuclear plants age, repairs will be required to extend the life of certain components. One commonly used repair technique is temperbead welding,

whose application is governed by the American Society of Mechanical Engineers' (ASME) Boiler and Pressure Vessel Code. ASME Code, however, has

traditionally restricted the use of temperbead welding to a surface area no larger than 100 square inches, thereby limiting its applicability. EPRI

undertook an engineering analysis to determine whether larger repairs could be conducted without deleterious stress effects on the repaired component.

| |

|

| |

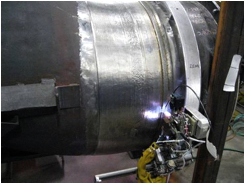

36-inch-diameter optimized weld overlay mockup during weld application. |

Larger temperbead weld repairs are primarily intended to support weld overlays for crack-sensitive low alloy steel pressure vessel connections to

piping welds (dissimilar welds), such as the steam generator, pressurizer, and/or reactor vessel nozzles. Developing new or revised Code rules for such

repairs requires significant effort to establish the technical basis and to demonstrate its safe application. EPRI performed a series of finite element

based residual stress evaluations for temperbead weld overlay repairs over ferritic materials (carbon and low alloy steels) to collect the data

necessary to determine whether such a technical basis could be developed.

Finite element analysis results showed that increasing the area of the temperbead overlay over the ferritic material improves the residual stresses in

the weld metal and reduces the likelihood for new stress corrosion cracking initiation following overall application. Notably, the residual stresses

and radial variations determined for the 500 in², 750 in² and 1000 in² temperbead repairs were consistent with expectations and would

not preclude the use of the temperbead process for weld overlays up to and beyond 1000 in². In fact, the residual stress results illustrate that

at the weld metal, on the inside surface of the component, the axial and hoop residual stresses diminish as weld overlay area increases.

This Code change is now available for nuclear plant application. One U.S. utility, in fact, recently used the new 1000 in2 limit in applying

an optimized weld overlay to a large-bore core flood weld location.

For more information, contact Artie Peterson at 704-595-2605 or arpeters@epri.com or Greg Frederick at 704-595-2571 or gfrederi@epri.com.

|