| Survey data enables nuclear plant owners to review flaw indication and failure experience, which can inform mitigation and inspection planning.

The Materials Reliability Program’s Inspection Data Survey Report (MRP-219, Revision 5, Report No. 1021011) summarizes inspection data collected from U.S. pressurized water reactors on a biannual basis. Utilities report the total number of components, number of components inspected, inspection methods, and inspection results for alloy 600/82/182 and alloy 690/52/152 components in the reactor pressure vessel upper and lower heads and pressurizer and reactor coolant system piping butt welds. Data for stainless steel residual heat removal mixing tee inspections is also requested.

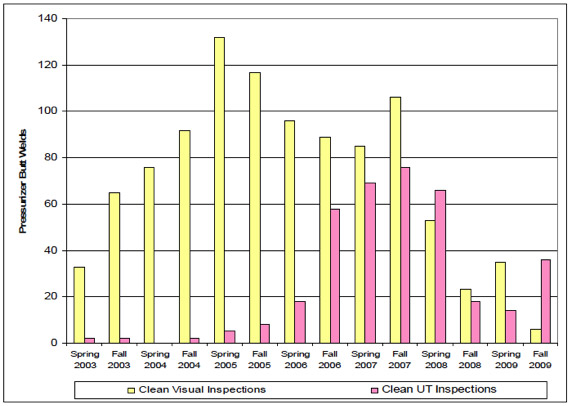

Data has been collected for outage seasons going back to spring 2003, and the current revision includes results through fall 2009. The survey information allows utilities to review flaw indication and failure experience, which can inform mitigation and inspection planning, as well as associated outage contingency planning. For example, some utilities may decide to apply preventative weld overlays to hot leg locations based on the number of indications previously found and the successful application of overlays in pressurizer locations. The current revision shows that ultrasonic testing is more likely to indicate flaws than penetrant testing and that butt welds with fabrication repairs are more likely to have confirmed flaws later on than those without.

The data also provide quick visual confirmation that utilities are inspecting components per industry guidelines. For example, volumetric ultrasonic inspections of pressurizer butt welds peaked in 2007 and 2008 in response to recommendations in the Materials Reliability Program’s Primary System Piping Butt Welds Inspection and Evaluation Guidelines. These guidelines also allowed for later implementation of inspections for less susceptible butt welds exposed to cold leg temperatures, and those components have been inspected in more recent outages.

The Materials Reliability Program will continue collecting this data to document industry inspection trends for as long as it remains relevant and useful in managing materials aging. Data for spring 2010 has already been received and revision 6 of this report is being assembled. For more information, contact Jessie Farias at 650.855.2061 or jfarias@epri.com.

|