| Updated guides on freeze sealing and on-line leak sealing will reflect operating experience, material changes, and technology advances since the original guidance was issued.

Recent events at nuclear power plants have brought attention to several plant issues for which guidance exists, but where technical updates are necessary due to operating experience, new methods, material changes, technology advances, and workforce changes. One area where EPRI is developing updated guidance is in sealing technology, a maintenance approach used to address fluid leakage. Two updated sealing guides will be published in 2011.

| |

|

| |

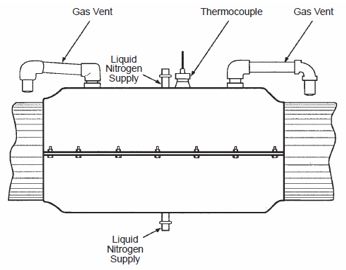

Typical Freeze Fixture for Piping Using Liquid Nitrogen |

EPRI issued guidance on freeze sealing, or ice plugging, of power plant piping in November 1997 (EPRI report TR-016384 R1). This technology is frequently used to isolate equipment for maintenance, thereby limiting impacts on outages and on-line activities. The original guidance addressed a number of application considerations, including the piping’s metallurgical properties, cooling methods, contingency planning, and industrial safety practices. Operating experience since 1997 has identified several technical issues that warrant an update.

For example, several nuclear plants have expressed concern about martensitic transformation in austenitic stainless steels when subjected to freeze sealing, which can cause brittle behavior in otherwise ductile austenitic stainless steels. The update will address the risks and mitigation options associated with this martensitic transformation.

The update will also describe precautions for providing adequate ventilation when performing freeze sealing. Liquid nitrogen, which is often used in freeze sealing applications, is an asphyxiant and could present a health hazard to workers.

EPRI issued guidance on on-line leak sealing (NP-6523-D) in 1989. This document addressed on-line leak sealing practices at that time, providing guidance on the effects of on-line leak sealing on pressure boundaries, chemical content of leak sealing compounds, sealant injection pressure, and other issues based on operational experience.

The updated guide will examine techniques and lessons learned that have been adopted by leak sealing companies to address problems encountered over the past 20 years. For example, consider one near-miss event at a U.S. nuclear plant involving valve bonnet bolting that failed unexpectedly during leak sealing preparation activities. The root cause was traced to intergranular stress corrosion cracking of the carbon steel fasteners. Many personnel are not aware that carbon steel components can experience intergranular stress corrosion cracking just like stainless steels. The updated guidance will identify and characterize precautions that utility and vendor personnel could take to reduce such risks.

For more information on these updates, contact Marty Bridges at 704-595-2672, mbridges@epri.com.

|