| Cooling tower reliability issues at several nuclear power plants have prompted the development of guidance on inspection and maintenance practices critical to improved performance and long-term health.

Several recent cooling tower failures have focused attention on enhanced inspection and maintenance practices. Forthcoming guidance from EPRI will help nuclear plant owners improve cooling tower performance and develop more effective asset management plans.

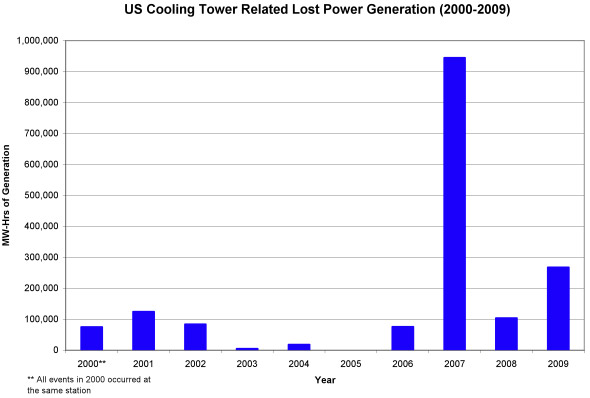

Cooling tower failures and other reliability issues can result in significant lost generation and emergent resource expenses at nuclear power plants, as shown in the accompanying figure. Some plants have had to reduce power because of the inability of cooling towers to comply with plant effluent limits. In addition, images of collapsed cooling towers can lower public confidence in nuclear power, even if such collapses represent low risks to nuclear safety.

EPRI’s Nuclear Maintenance Application Center is compiling industry best practices and lessons learned for cooling tower operation and maintenance based on experience from U.S. and non-U.S. nuclear plants. The guidance document, available in late 2010, will help utilities determine how to inspect cooling towers for structural degradation and how to maintain cooling towers to achieve desired thermal performance. Maintenance frequencies and maintenance methodologies are defined for all parts of the tower. Key findings include:

- Wooden cooling towers are often the most vulnerable to degradation, but towers made of concrete and fiberglass are also susceptible depending on operating conditions. Towers in aggressive water conditions, for example, may experience corrosion and deterioration of structural members.

- Since periodic replacement of wood members or replacement of towers is inevitable, an asset management plan for wooden towers should include funding for this large expenditure.

- When retrofitting with high-efficiency fill, carefully consider factors such as water chemistry and quality. For example, weighing of sample fill locations where high-efficiency fill or water with high particulate content are utilized may prevent major fill collapses by providing early warning.

- The best advice for preventing fouling is to understand the water chemistry and particulate content, select fill with water chemistry in mind, and strive to prevent oil from entering the system.

- Incentives for meeting performance criteria and penalties for failure to achieve desired performance during cooling tower initial installations and major maintenance can help ensure the utility achieves the desired results for the investment.

- Consider the French approach to a more rigorous approach to inspecting concrete natural draft towers using methods such as digital topography to map defects and detect leaning.

For more information, contact Marty Bridges at 704.595.2672 or mbridges@epri.com or Gary Boles at 704.595.2781 or gboles@epri.com.

|

|

| Concrete Degradation |

Wood Degradation |

|