| In light of specific instances where counterfeit items have been found at nuclear plants, EPRI is developing industry guidance to improve detection and identify risk mitigation options.

The U.S. Immigration and Customs Enforcement (ICE) agency estimates that counterfeiting costs U.S. industry 750,000 jobs annually. Thousands more jobs are at risk around the world. In federal fiscal year 2008, ICE and the Customs and Border Protection agency made more than 14,000 seizures of counterfeit goods, valued at more than $272.7 million, representing a 38% increase in value over 2007.

Enormous growth in the manufacturing capabilities of regions such as Asia has increased the number of counterfeit, fraudulent, and substandard items (CFSIs). Recent high-profile examples related to pharmaceuticals, pet food, and lead paint in toys highlight the extent of the issue and the growing level of concern. Further, with counterfeiters using increasingly sophisticated methods and capabilities, counterfeit and substandard items could end up in the products of unknowing legitimate suppliers unless measures are taken to ensure otherwise.

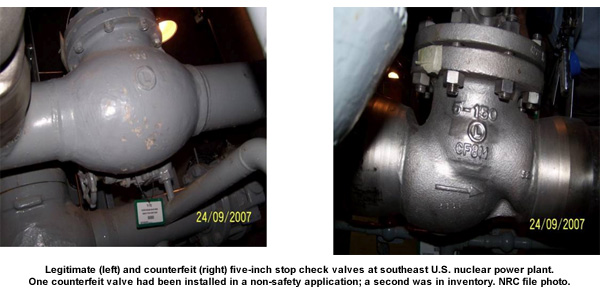

In the nuclear industry, several CFSIs have been detected prior to being placed in active inventory, and several others have been detected only after installation in commercial facilities. Fortunately, the items did not fail in service before corrective actions were implemented. While some effective guidance on CFSI detection is contained in a 1990 EPRI Report (NP-6629, Appendix C), the guidance is not comprehensive enough to completely address the resources and capabilities of today’s counterfeiters.

Because of the economic and safety implications associated with CFSIs, the U.S. government formed an interagency task force to address the issue. This task force includes the Nuclear Regulatory Commission. In 2008, the NRC issued an Information Notice (2008-04) specific to CFSIs, “Counterfeit Parts Supplied to Nuclear Power Plants.” NRC also asked EPRI to address this issue in its technical procurement programs. Through the Plant Support Engineering Program, EPRI incorporated a module on the subject into its Nuclear Vendor Procurement and Nuclear Utility Procurement courses. In addition, EPRI has delivered the module at Joint Utility Task Group (JUTG) and Nuclear Procurement Issues Committee (NUPIC) meetings, as well as the NUPIC auditor training conference. To minimize the risk of experiencing a failure attributable to a counterfeit, substandard or fraudulent item, Plant Support Engineering is developing detailed CFSI guidelines in 2009. The Technical Advisory Group includes an expert with experience addressing this issue at Department of Energy facilities, as well as several JUTG steering committee members, NUPIC auditors and other utility representatives.

Although in the early stages of development, the report is expected to address:

- Historical issues with CFSIs and the industry’s response

- Examples of current issues with CFSIs in commercial nuclear power plants

- Contributing factors to the emergence of CFSIs as a serious risk

- Existing sources of guidance, data and information, including various government agencies (defense, energy, space, commerce) and high-tech industries (military, aviation)

- Benchmarking of effective CFSI programs and lessons learned for both current and new plants

- Risk mitigation options, including a global database or other working tool.

For more information, or if you are interested in participating on the technical advisory group, contact Marc Tannenbaum at 704.595.2110 or mtannenbaum@epri.com.

|